welding times speed up your manufacturing process.

system power join even larger EV applications safely.

cross-sections can be welded reliably & with ideal conductivity.

White Paper: 3 Boosters for E-Mobility

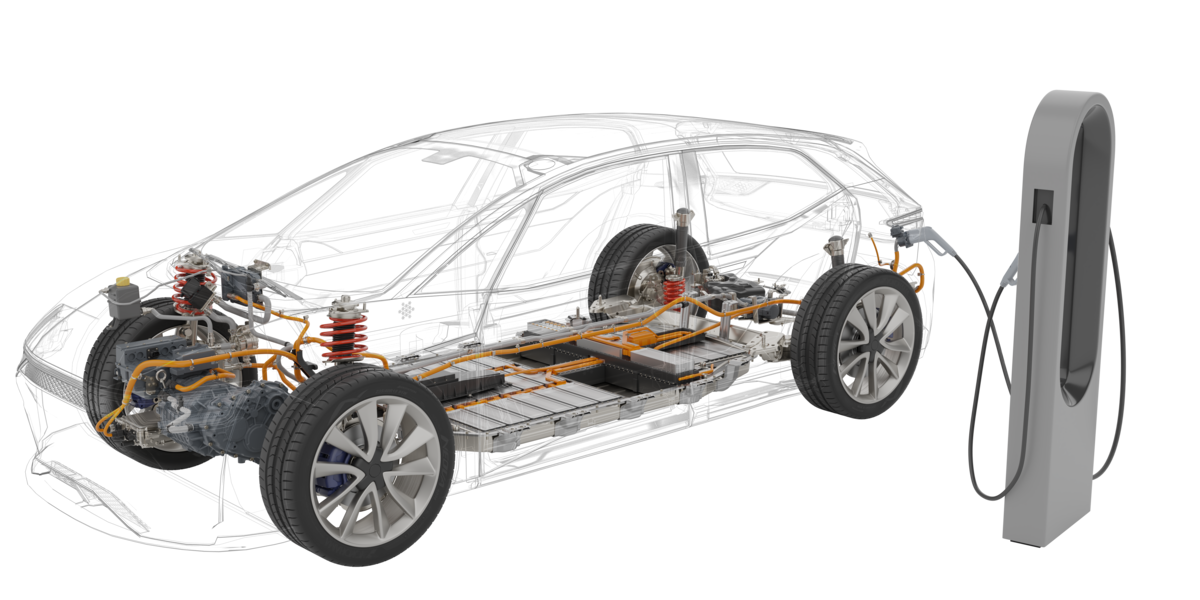

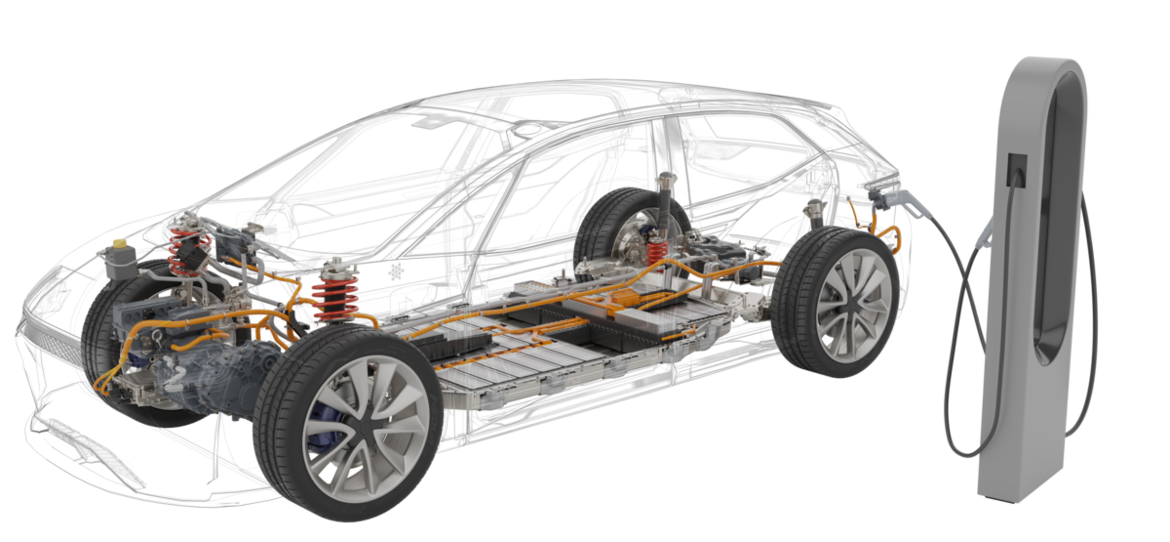

From wire-to-terminal and busbar applications to batteries: Numerous applications in electric vehicles benefit from ultrasonic welding as a joining technology. Learn how to overcome the key challenges of e-mobility with ultrasonic welding!

Use the technology to permanently:

- Reduce production costs

- Increase the range of the EV

- Make manufacturing processes more efficient & sustainable

Successfully solved e-mobility applications

Ultrasonic Welding for Superior Electrical Conductivity

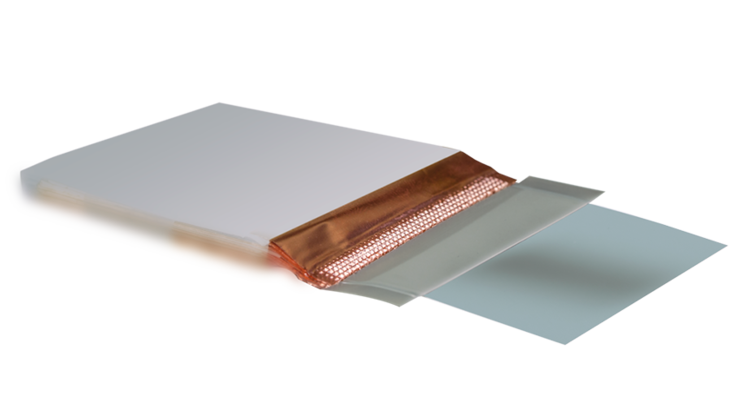

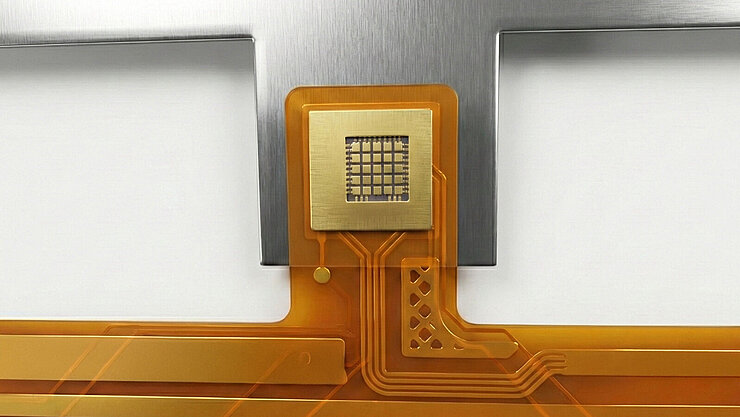

When providing consulting services to a leading manufacturer of electrical connectors, hidden potential for increasing efficiency and product quality was identified. As part of a joint project, the existing crimping process was replaced by ultrasonic welding. This led to a significant improvement in electrical conductivity and connection stability.

FAQ – Ultrasonic Welding for eMobility

Ultrasonic welding of metals has several advantages over conventional welding methods such as soldering, crimping or laser welding:

- Perfect for mixed connections: Ultrasonic welding is a mechanical joining process that works without melting. This makes ultrasonics perfect for welding copper, aluminum or other non-ferrous metals together.

- Speed: The welding process with ultrasonics only takes fractions of a second. Since smaller applications don't require additional cooling times, production cycles can be significantly accelerated.

- Reliability: The specification and monitoring of numerous welding parameters ensures precise and reproducible welding results. This is a decisive advantage, especially when welding sensitive and small metal parts, such as in batteries.

- Cost efficiency: Ultrasonic welding requires very little energy, thereby reducing electricity costs. In addition, components such as connectors often require less material and their contact surface is easier to manufacture, which saves additional costs.

- Sustainability: Reduced energy consumption also makes the entire manufacturing process more sustainable. This helps to comply with legal regulations.

- Safety: Ultrasonics welding machines are designed with a special focus on user safety. The ULTRASAFE X in particular ensures the health and safety of the user with its large operating area, safety glass, and height-adjustable table.

- Gentle: Thanks to our modern ultrasonic welding systems, welding forces can be controlled very precisely, even in the low range of 5 N. This enables a particularly gentle joining process and prevents changes to the material outside the welding area.

Learn more about the benefits of ultrasonic welding for application in our free white paper.

Ultrasonic welding ensures extremely strong and reliable connections — even for demanding applications in electromobility. The connection is created by high-frequency mechanical friction under pressure without melting the material. The result: a tight connection with excellent electrical contact.

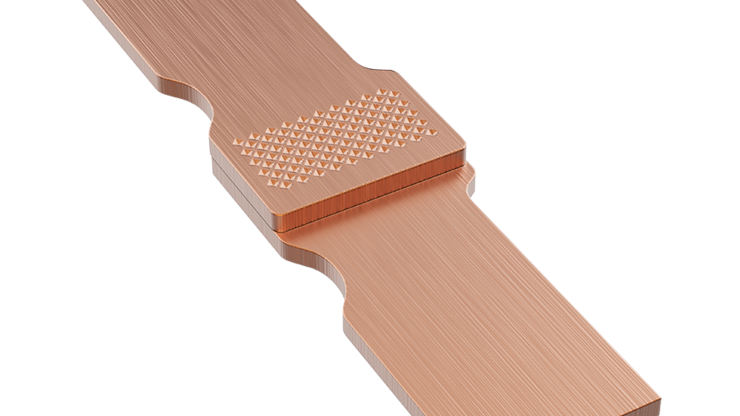

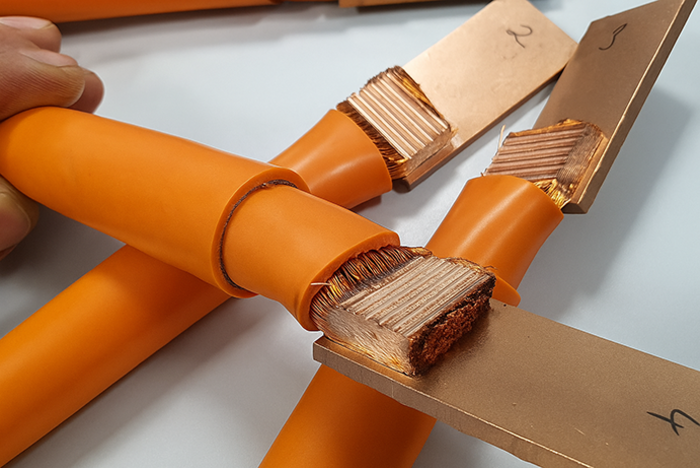

Ultrasonics is particularly convincing due to its high mechanical strength: busbars and wire-to-terminal applications welded with ultrasonics can withstand enormous forces — both in the shear and peel direction. Depending on the application, tensile forces of 5,000 N to 10,000 N and more are possible. The connection remains stable even during temperature cycles and vibrations, making it ideal for safety-critical applications.

For engineers and process owners, this means reliable, durable connections that meet the highest requirements in industrial production — without any additives and minimum thermal stress on the material.

Learn more about the benefits of ultrasonic welding for E-Mobility applications in our free white paper.

Yes, ultrasonics is perfectly suited to permanently join different non-ferrous metals. Unlike thermal processes, where different melting points and material properties often lead to problems, ultrasonics can be used to join mixed metals such as copper-aluminum or brass-aluminum firmly and reliably.

The welding process is purely mechanical – without melting, without solder. This effectively breaks up oxide layers, creating a highly conductive, corrosion-resistant joint. This is a decisive advantage, especially in e-mobility.

This makes ultrasonic welding the ideal solution for connecting different non-ferrous metals.

Learn more about the benefits of ultrasonic welding in our free white paper.

Modern ultrasonic welding machines are ideal as ergonomic manual workstations or as integrated systems in automated production lines. The patented architecture of the ultrasonic components enables welding with minimum or even no cooling times, so that even large cross-sections with up to 200 mm² or thicker busbars of up to 6 mm can be welded in the shortest possible time.

Thanks to short welding times of 100 to 250 ms and the precise control of welding parameters, the process is perfectly suited for automated production.

Individual welding machines used in manual processes are designed to be user-friendly and can be loaded quickly thanks to large engagement areas. This enables cycle times of 7 to 12 seconds for smaller busbar applications, for example.

Learn more about the benefits of ultrasonic welding for e-mobility applications in our free white paper.

Thanks to our modular product portfolio, we have the right solution for every need.

Our ULTRASAFE X is a manual work station with a special focus on safe, intuitive, and ergonomic working. Individual auxiliary functions and modules can be added as required. With a large operating area and a power output of up to 12 kW, it is perfectly suited for busbar and wire-to-terminal applications.

Our HiS VARIO X is our versatile system for integration into automated production lines. We are happy to assist you as your trusted advisor for all questions relating to integration.

Our HiS VARIO P and S are our solutions for the safe welding of battery applications. They are available as manual work stations and as systems for integration into automated manufacturings.

Partner with us to increase your efficiency and speed

Contact our team to discover how our premium solutions can increase the output of your e-mobility application. We look forward to hearing from you!